Excavation machines are powerful machines that have a vital role in building, extraction, and demolition projects. Grasping the key parts of an excavator can considerably enhance your ability to handle the machine properly and maintain it adequately. No matter if you are a experienced operator or a novice to the heavy equipment industry, familiarizing yourself with the basic parts of an excavator will help you understand the engineering behind these impressive machines.

At first glance, an excavator may seem like a challenging piece of equipment, but it can be categorized into several essential parts. From the sturdy undercarriage that carries its weight to the versatile boom and bucket that enable it to dig and lift, each element plays a vital role in the machine's performance. By gaining knowledge into the different excavator parts, you can secure better performance, streamline operations, and support to the life span of the equipment.

Main Components of Excavators

Excavators are complex devices with several key parts that function collaboratively to carry out a variety of tasks. The undercarriage is one of the primary components, consisting of the tracks, rollers, and sprockets. This part offers support and mobility, enabling the excavator to traverse different terrains efficiently. The undercarriage is designed to evenly spread the weight of the machine evenly, providing a solid foundation for functioning.

The boom and arm are crucial for the excavator's functionality, enabling it to reach, dig, and lift materials. The boom is the long, hinged arm that extends from the primary body of the machine, while the arm, also referred to as a dipper or stick, is attached to the bucket. Together, these components allow for a range of motion that is vital for excavation tasks. The hydraulic systems power the movement of both the boom and arm, providing the necessary force to handle heavy loads.

Lastly, the cab or operator's area is crucial for control and operation. This enclosed space houses all the controls and instrumentation required for the operator to securely maneuver the excavator. cat parts is designed for visibility, helping the operator to see the job site clearly while providing comfort during extended hours of work. The cab is fitted with safety features and technology that enhance the overall efficiency and safety of the excavating process.

Attachment Varieties and Capabilities

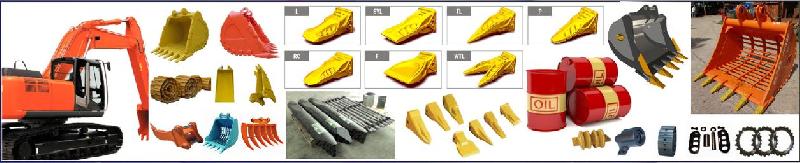

Excavators are incredibly flexible machines, primarily due to the variety of tools that can be used. The standard bucket is the primary attachment, perfect for excavating and transporting soil, gravel, or waste. Available in various sizes and shapes, buckets can be adapted for specific tasks like trenching or leveling. The design allows operators to switch out buckets rapidly, making the excavator adaptable for varied job requirements.

In addition to buckets, alternative popular attachments include hydraulic thumbs, which assist in holding and gripping objects, and augers used for drilling holes in the earth. These attachments significantly boost an excavator's capability on a construction site, allowing it to perform tasks like tree removal or post digging efficiently. Concrete breakers, or hammers, are also popular attachment, ideal for breaking concrete or stone during demolition work.

Specialized attachments such as grabbing tools and rippers increase the machine's capabilities. Grapples are great for handling large materials like logs or scrap metal, enhancing overall efficiency. Ripping tools, on the contrary, are built to penetrate tough soils or shattering through hard ground, making them invaluable for clearing land or site preparation. With a diverse selection of attachments, excavators can be modified to handle various tasks, making them vital equipment in construction and land design projects.

Care and Maintenance Tips

Regular upkeep of an excavator is essential to guarantee its longevity and peak efficiency. One key factor of maintenance is to maintain the machine free of debris, particularly the hydraulics components. Dirt and debris can lead to damage and create more significant issues if not resolved promptly. Plan regular cleanings, particularly after using the excavator in muddy or dry conditions.

Another critical maintenance task is to frequently check fluid levels, including hydraulic fluid, engine oil, and coolant. Insufficient fluid levels can result in engine overheating and hydraulic failures. Additionally, check hoses and seals for any indicators of damage or leaks, as this can hinder suboptimal operation and raise repair costs over time.

Lastly, consistent inspections and servicing of the excavator’s tracks and undercarriage are crucial. This area is subject to intense stress and strain. Check for signs of damage or misalignment, and make sure that the tracks are adequately tensioned. Maintaining these components in optimal condition will maximize productivity and minimize downtime caused by unexpected repairs.